Scenario calculator | Visualise the future of the petrochemical industry under scenarios of your choice

What are the options? Try our calculator to evaluate the implications of policy decisions on the future of the petrochemical industry.

The C-THRU Petrochemicals Scenario Calculator shows how a future petrochemical sector could respond to different levels of ambition for a wide range of emissions-reduction levers. It builds on existing static projections and modelling to allow anyone to explore what combinations of technical and societal changes can make a big difference to reducing this high-emitting sector’s emissions.

The underlying model draws together baseline data and projections from a wide variety of industry data and peer-reviewed literature. Changes in demand for plastics and fertilisers feed through to drive demand for primary chemicals such as ethylene and propylene, which can be supplied from fossil-based or bio feedstocks, from renewably-powered hydrogen, or recycled waste polymers. However, many of these technologies currently have limited capacity, so the model shows how large emissions reductions can only be achieved by activating many levers together.

Emissions dashboard | Visualisation of global petrochemical production emissions

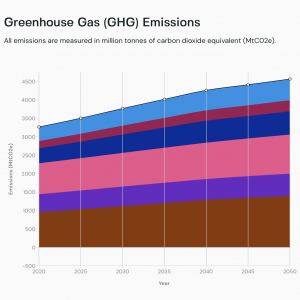

Greenhouse gas emissions from just the production stage of petrochemicals represent approximately 4% of all anthropogenic emissions. Visualise their breakdown across products and the globe with our latest interactive dashboard.

Reports

Deep Dives | Carbon clarity in the petrochemical supply chain

June 15, 2023

C-THRU exists to bring greater clarity, transparency, and breadth to our understanding of emissions from the petrochemical sector. Here we present preliminary results and insights from the second year of the project. In six ‘deep dives’, we showcase the work the team has been doing to shed light on where emissions are released throughout the life cycles of chemical products, the actions we can take to reduce them, and the knock-on effects for other processes within and beyond the industry.

The Critical Review | Carbon clarity in the petrochemical supply chain

October 25, 2022

The decarbonisation of the petrochemical sector is challenging given the complexity of supply chains and thermodynamic constraints of the chemical reactions. Emissions are released throughout their life cycles, with varying stages dominating for different products. Mitigation options are therefore less straightforward than in other industries, requiring a system-wide approach. The nature of the sector also makes data collection and analysis challenging, meaning there is currently no reliable, comprehensive picture of GHG emissions or energy, mass, and trade flows of the petrochemical sector.

Journal articles

Coming Soon | Greenhouse gas emissions from global petrochemical production (1978-2050)

Fanran Meng, Luke Cullen, Rick Lupton, Jonathan M. Cullen, May 16, 2024

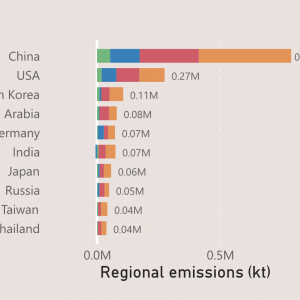

The petrochemical industry is responsible for 13% of global industrial and 3.5% of total greenhouse gas (GHG) emissions1,2. However, a detailed account of facility-level emissions does not exist, clouding decision making for decarbonisation in the sector. To address this gap, we map historical, present, and anticipated emissions from 37,379 production facilities, assessing trends across country, product-type, emissions source, GHG-type, uncertainty and time. We develop a bottom-up emissions assessment covering 81 chemicals and 2,043 manufacturing processes, using production volumes, process recipes, thermodynamic principles, and fully quantified uncertainties. We show that global GHG emissions from petrochemical production are 2.0±0.8 GtCO2e in 2023, rising to 3.0±1.2 GtCO2e in 2050. Decarbonisation is challenging due to fossil feedstock use, releases from process reactions, long infrastructure lifespans, and high-temperature heat requirements; analyses and action are hindered by inadequate granularity for emissions accounts1,3–5. Our scenarios suggest that efficiency improvements, alternative feedstocks and carbon capture technologies must be implemented quickly, prioritising the highest-emitting facilities. Demand reduction and power grid decarbonisation, especially in China, the US, and India, are needed to achieve net-zero emissions by 2050. Our comprehensive analysis provides insights for industry, academics, and policymakers, for targeting effective decarbonisation in the petrochemical sector.

Coming Soon | Evaluating the potential to reduce the global demand for virgin polymers

Yunhu Gao & André Cabrera Serrenho, May 16, 2024

The widespread use of polymers leads to several environmental challenges, particularly greenhouse gas (GHG) emissions and ecosystem contamination. Yet, the global mitigation potential of possible interventions has not yet been quantified. This would require a high-resolution model to anticipate the future demand for polymers, and the potential impacts of demand reduction and recycling. Here, we present such a model to estimate the production, trade, consumption, and the accumulation in service of 14 polymers across eight world regions. Current trends could lead to doubling the annual global demand and waste generation of polymers by 2100. But any further increases could be avoided by either limiting the stock of polymers in service globally or by maximising the deployment of mechanical and chemical recycling technologies.

Coming Soon | Consistency and completeness of data on the global petrochemicals sector’s emissions

Banafsheh Jabarivelisdeh, Enze Jin, Phillip Christopher, and Eric Masanet, May 16, 2024

Ammonia production is responsible for around 35% of the CO2 emissions associated with the global chemical sector. In this study, a bottom-up model with high technical and economic resolution is implemented to assess potential least-cost pathways to achieve a net-zero U.S. ammonia industry by 2050.

Coming Soon | Achieving net-zero U.S. ammonia: Technology and policy options and their emissions, investment, and cost tradeoffs

Dominika Malkowska & Rick Lupton et al. May 16, 2024

In this study the consistency and completeness of two publicly-available datasets (PRODCOM and UNFCCC) is analysed against a proprietary industry database of petrochemical facilities (ICIS Supply and Demand), comparing production quantities and estimated emissions. This provides an innovative global assessment of the potential impact of inconsistencies and data gaps on our ability to model and monitor the operation and emissions of the global petrochemical industry.

Connected, Complex, and Carbonized: The Geographic Archetypes of the Petrochemicals Sector

Ella T. Jennings, Penny J Hamlin, Chris Hamlin and Jonathan M. Cullen, May 16, 2024

The petrochemicals sector is known to be “hard-to-decarbonise” due to its innate requirement for oil, high greenhouse gas emissions, and highly interconnected and complex supply chains. The sector’s complexity makes it difficult to decipher how, when, and where to intervene. Every country has a different level of embroilment in the petrochemical sector, further complicating the solution space, with no one-fits-all policy recommendations. There have been no previous attempts in literature to perform a categorization on the petrochemical industry. This research fills this gap by examining the structure of the petrochemical sector to categorize countries into groups which will respond similarly to different decarbonisation solutions.

Coming Soon | Re-evaluation of end-of-life treatment options for plastics

Fanran Meng & Jonathan M. Cullen, May 16, 2024

This study re-evaluates recycling, landfill, and incineration for commodity polymers (PET, PE, PVC, PP, PS, PUR, and ABS). This involves the compilation of a repository of life cycle inventory data, a review of the academic and grey literature, and some original modelling, which are synthesised to create a decision-making framework. Policy options for reducing the greenhouse gas emissions of the different EOL options are discussed.

Coming Soon | Exploring the technically-plausible solution space, levers and interactions for emissions reduction in the global petrochemical industry

Stephen S. Doliente, Rick Lupton et al., May 16, 2024

Eliminating carbon emissions from the petrochemical sector will involve changes to a complex system of feedstocks, processes, energy, materials, products, and waste management. This complexity and the scale of change required mean it is challenging to include both breadth of supply-side and demand-side changes, and the depth needed to make sure solutions are technically plausible. Inspired by the UK MacKay energy system calculators, we develop an interactive petrochemical systems calculator model which shows how a future global petrochemical sector could respond to different levels of ambition for a wide range of emissions-reduction supply-side and demand-side levers.

Coming Soon | Programmatic Material Flow Analysis: driving process systems through logic

Rick Lupton, May 16, 2024

Models of material flows and processes used for Life Cycle Assessment and Material Flow Analysis are most commonly linear in nature, deploying fixed process in different proportions to meet demand according to a system of linear matrix equations. However, this approach cannot handle more complicated situations, such as when processes have limited capacity and should be dispatched in order of preference until capacity is exhausted. The solutions can also be hard to explain, since the resulting process operations are the result of the numerical solution to a large matrix inversion. We therefore propose a new modelling approach based on defining the logical steps through which flows are determined. The result is an efficient and explainable model which in simple cases is simple to define, but has the flexibility to embed more complex logic.

Coming Soon | Calibrating Energy, Mass, and Money Stocks and Flows within the Human and Resources with MONEY Economic Growth Model

Carey King, May 16, 2024

This paper summarizes the effort to calibrate the HARMONEY model framework to the United States economy divided into seventeen productive sectors plus the household and government sectors. To do this, we have allocated approximately 100 gigatonnes of mass stock in the U.S. economy among fifteen categories of capital, such as roads, buildings, and power plants.

Reducing uncertainties in greenhouse gas emissions from chemical production

Luke Cullen et al., March 26, 2024

Uncertainties in greenhouse gas emissions estimates for petrochemical production have lacked quantification globally, impacting emissions reporting and decarbonization policymaking. Here we analyze cradle-to-gate emissions of 81 chemicals at 37,000 facilities worldwide, assessing 6 uncertainty sources.

Replacing Plastics with Alternatives Is Worse for Greenhouse Gas Emissions in Most Cases

Jonathan Cullen, Fanran Meng and Miguel Brandão , January 30, 2024

Replacing plastics leads to higher full life-cycle emissions using alternative materials in most current applications.

Solutions for recycling emerging wind turbine blade waste in China are not yet effective

Jonathan Cullen, Fanran Meng et al, December 12 2023

Here we predict the quantity and composition of wind turbine blade waste based on historic deployment, compiling a high-resolution database containing 14 turbine capacities (150–5500 kilowatts) based on 104 turbine models.

China’s bulk material loops can be closed but deep decarbonization requires demand reduction

Lulu Song, Stijn van Ewijk, Eric Masanet, Takuma Watari, Fanran Meng, Jonathan M. Cullen, Zhi Cao & Wei-Qiang Chen, September 11, 2023

Here we show that, by 2060, China could source most of its required bulk materials through recycling, partially attributable to a declining population.

Recycled Polymers As a Feedstock for Chemical Manufacturing Supply Chains in the United States: A Network Analysis for Polyethylene Pyrolysis

Zhichao Chen, Yosuke Kimura, and David T. Allen, April 3, 2023

For chemical recycling of plastic wastes to be viable, chemical products generated in recycling need to find markets. A network model of the U.S. chemical manufacturing industry was used to assess at what cost points, and the extent to which, chemical products from thermal pyrolysis of polyethylene might find markets in the current U.S. chemical manufacturing industry.

What to Do about Plastics? Lessons from a Study of United Kingdom Plastics Flows

Michał Drewniok, Yunhu Gao, André Cabrera Serrenho and Jonathan Cullen, March 9, 2023

New study of UK plastics flows from shows that 1/3 of related GHG emissions could be reduced by increasing recycling capacity and halving per capita demand for packaging.

Planet-compatible pathways for transitioning the chemical industry

Fanran Meng, Eric Masanet, André Cabrera Serrenho, Jonathan Cullen, February 14, 2023

New paper presents seven planet-compatible pathways the chemical industry could follow to reach net zero by 2050. Through a combination of demand-side and supply-side strategies, it is possible to transform the industry so that it is a force for environmental good rather than a planetary-boundary-breaking threat.

Greenhouse gas emissions from nitrogen fertilizers could be reduced by up to one-fifth of current levels by 2050 with combined interventions

Yunhu Gao and André Cabrera Serrenho, February 9, 2023

New study shows that emissions from global fertilisers could be cut by 84% by implementing a combination of policy solutions and technological measures. 2/3 of emissions from fertilisers are released during the use phase, meaning that both demand-side and supply-side interventions will be required to mitigate emissions.

Model-based Analysis of Ammonia Production Processes for Quantifying Energy Use, Emissions, and Reduction Potentials

Banafsheh Jabarivelisdeh, Enze Jin, Phillip Christopher, and Eric Masanet, January 25, 2023

New study assesses the emissions reductions of actions to improve the efficiency of existing ammonia production processes. Our model reveals the emissions-saving potential of short-term interventions to retrofit existing production facilities for greater efficiency.

Recycled Polymers As a Feedstock for Chemical Manufacturing Supply Chains in the United States: A Network Analysis for Polyethylene Pyrolysis

Zhichao Chen, Yosuke Kimura , and David T. Allen, November 11 2022

A network model of U.S. chemical manufacturing was used to assess network impacts and cost points for using recycled polyethylene.

Ammonia Production Processes from Energy and Emissions Perspectives: A Technical Brief

Banafsheh Jabarivelisdeh, December 13, 2022

Ammonia is a key chemical produced at large volumes to meet vast global demands for products such as fertilisers. It plays a key role in the global economy, but this is not without cost to the planet. Ammonia production also requires large amounts of energy and releases significant quantities of greenhouse gases. This brief includes technical descriptions of the main ammonia production technologies to build understanding of the current production pathways, the associated energy usage, their process emissions statuses, and the potentials for sustainable ammonia production.

Plastics and climate change—Breaking carbon lock-ins through three mitigation pathways

Jonathan Cullen, May 11, 2022

The plastic industry is dependent on fossil fuels in various ways that result in strong “carbon lock-ins” throughout the value chain and large and growing CO2 emissions. The industry must decarbonize to reach global net-zero pledges.

Interdependence of Growth, Structure, Size and Resource Consumption During an Economic Growth Cycle

Carey King, May 5, 2022

Scientists and economists often seek to understand the linkages among natural resources consumption and the cost of resources in tandem with the growth rate, size, and structure of complex systems. These systems can be biological organisms, ecosystems, and national or global economies.

Mapping Greenhouse Gas Emissions of the U.S. Chemical Manufacturing Industry: The Effect of Feedstock Sourcing and Upstream Emissions Allocation

David Allen, April 27, 2022

Greenhouse gas emissions from 135 commodity chemical manufacturing processes in the United States were estimated based on benchmark process data from U.S. petrochemical manufacturing models. Total greenhouse gas emissions of the 135 processes evaluated are dominated by a small number of process types that have high emission intensities (emissions per mass of product produced) and high production volumes.

Wind Turbine Blades Using Recycled Carbon Fibers: An Environmental Assessment

Jonathan M. Cullen, January 18, 2022

Polymers reinforced with virgin carbon fibers (VCF) are being used to make spar caps of wind turbine (WT) blades and polymers with glass fibers (GF) to make skins of the blade components. Here, we assess the life cycle environmental performance of the hybrid blades with spar caps based on VCF and the shells and shear webs based on RCF (recycled CF) composites (RCF-hybrid). The production of the WT blades and associated reinforced polymers is assumed to occur in Sweden, with their uses and end-of-life management in the European region.

A Network Analysis of the Petrochemicals Industry in Western Europe

Chris and Penny Hamlin, April 16, 2021

This paper examines the role of networks in establishing and sustaining industrial sectors and clusters, the consequent behaviours of those clusters and their participants, and ultimately the implications of the extended enterprise for participants, regulators and researchers.

Plastics in the UK

Jonathan Cullen, October 28, 2020

Plastics are ubiquitous in modern society, owing to their usefulness, durability and how cheap and easy they are to produce. This makes plastics both a blessing and a curse.